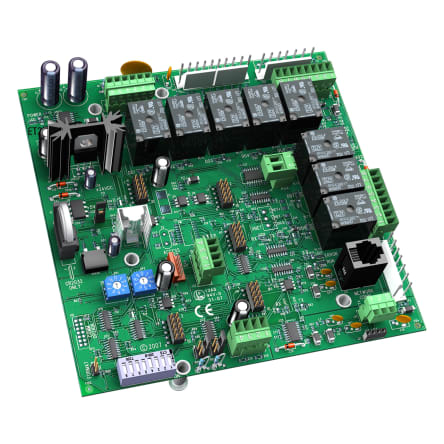

i-Vu® Open WSHP Controller

OPN-WSHPM

Product Integrated Controller

Carrier’s WSHP Open controller is an integrated component of a Carrier water source heat pump. The WSHP Open controller continuously monitors and regulates water source heat pump operation with reliability and precision. This advanced controller features a sophisticated, factory-engineered control algorithm that provides optimum performance and energy efficiency. The WSHP Open controller also features plug-and-play connectivity to the Carrier i-Vu System. The Carrier i-Vu System combines state-of-the-art Carrier equipment, plug-and-play controllers, and the powerful, web-based i-Vu user interface to form a cohesive, intuitive, and fully-integrated BACnet® Building Automation System.

For added flexibility, the WSHP Open controller is capable of stand-alone operation. Or, it can be integrated with any Building Automation System utilizing the BACnet, Modbus, or N2 protocols.

Application Features

- Controls 2 stages of DX cooling to maintain space temperature setpoint

- Integrated 2-position or modulating waterside economizer for optimized mechanical cooling

- Controls modulating or 2-position outside air damper to meet ASHRAE 90.1 requirements

- Built-in advanced control routines for zone level humidity control or zone level demand control ventilation (ASHRAE 62)

- Supports auxiliary modulating reheat, 2-position hot water/steam reheat, or electric heat

- Independent fan speed and compressor staging ensures quiet operation and maximizes latent heat removal for increased occupant comfort

- Modulating fan speed and compressor staging ensures safe unit operation

Hardware Features

- Compatible with Aquazone™ horizontal and Puron® vertical water source heat pumps

- Integrates easily into any BAS using BACnet, Modbus, or N2 protocols

- On-board hardware clock, remote occupancy input, and support for SPT/thermistor sensors provide stand-alone operation

- Easy startup and commissioning using Carrier’s BACview Handheld Service Tool

System Benefits

- Integrated Carrier airside linkage algorithm for plug-and-play integration with the Carrier WSHP System

- Fully plug-and-play with the Carrier i-Vu System

- Supports demand limiting for maximum energy savings

- Compatible with i-Vu Tenant Billing for tracking tenants’ after-hours energy usage

| BACnet Support | Advanced Application Controller (B-AAC), as defined in BACnet 135-2001 Annex L |

| Communication Ports | Network Comm port: EIA-485 port for BACnet MS/TP, Modbus RTU, or N2 communications

(protocol and baud rate are DIP switch selectable); Comm Option port: For connecting a LON Option Card; Local Access port: For system start-up and troubleshooting (115.2 kbps); Rnet port: For connecting Carrier communicating room sensors and Carrier’s touchscreen user interface |

| Inputs | 4 analog inputs: Dedicated to Relative Humidity, Indoor Air Quality, Supply Air Temperature, and

Leaving Condenser Water Temperature. AI’s have 10 bit A/D resolution. 4 binary inputs: Stage 1 Compressor Status, Condensate Overflow, Fire/Smoke Detector, and Fan Status (optional) |

| Outputs | 2 analog outputs: 1 dedicated to Outside Air Damper, and 1 configurable for either Auxiliary

Reheat or Waterside Economizer. AO’s have 10 bit D/A resolution. 8 binary outputs: Supply Fan (low, medium, and high), Compressor Stage 1, Compressor Stage 2, Reversing Valve, Auxiliary Heat/2-position Waterside Economizer, and Dehumidification. Relay contacts rated at 3A max @ 24VAC, configured normally open |

| Real Time Clock | Battery-backed real time clock keeps track of time in event of power failure |

| Battery | 10-year Lithium CR2032 battery provides a minimum of 10,000 hours of trend data & time retention during power outages |

| Protection | Incoming power and network connections are protected by non-replaceable internal solid-state polyswitches that reset themselves when the condition that causes a fault returns to normal. The power, network, input, and output connections are also protected against voltage transient and surge events. |

| Status Indicators | LED status indicators for network communications, run status, error, power, and all digital outputs |

| Controller Addressing | Rotary dip switches set BACnet MS/TP, Modbus, or N2 address of controller |

| Listed by | UL-873, FCC Part 15-Subpart B-Class A, CE EN50082-1997 |

| Environmental Operating Range | Operating: -40 to 158ºF (-40 to 70ºC)

10 to 95% RH, non-condensing Storage: -40 to 158ºF (-40 to 70ºC) 10 to 95% RH, non-condensing |

| Power Requirements | 24VAC +/- 10%, 50-60Hz, 14 VA power consumption, 26VDC (25V min, 30V max), single class 2 source only, 100 VA or less |

Application Features

- Controls 2 stages of DX cooling to maintain space temperature setpoint

- Integrated 2-position or modulating waterside economizer for optimized mechanical cooling

- Controls modulating or 2-position outside air damper to meet ASHRAE 90.1 requirements

- Built-in advanced control routines for zone level humidity control or zone level demand control ventilation (ASHRAE 62)

- Supports auxiliary modulating reheat, 2-position hot water/steam reheat, or electric heat

- Independent fan speed and compressor staging ensures quiet operation and maximizes latent heat removal for increased occupant comfort

- Modulating fan speed and compressor staging ensures safe unit operation

Hardware Features

- Compatible with Aquazone™ horizontal and Puron® vertical water source heat pumps

- Integrates easily into any BAS using BACnet, Modbus, or N2 protocols

- On-board hardware clock, remote occupancy input, and support for SPT/thermistor sensors provide stand-alone operation

- Easy startup and commissioning using Carrier’s BACview Handheld Service Tool

System Benefits

- Integrated Carrier airside linkage algorithm for plug-and-play integration with the Carrier WSHP System

- Fully plug-and-play with the Carrier i-Vu System

- Supports demand limiting for maximum energy savings

- Compatible with i-Vu Tenant Billing for tracking tenants’ after-hours energy usage

| BACnet Support | Advanced Application Controller (B-AAC), as defined in BACnet 135-2001 Annex L |

| Communication Ports | Network Comm port: EIA-485 port for BACnet MS/TP, Modbus RTU, or N2 communications

(protocol and baud rate are DIP switch selectable); Comm Option port: For connecting a LON Option Card; Local Access port: For system start-up and troubleshooting (115.2 kbps); Rnet port: For connecting Carrier communicating room sensors and Carrier’s touchscreen user interface |

| Inputs | 4 analog inputs: Dedicated to Relative Humidity, Indoor Air Quality, Supply Air Temperature, and

Leaving Condenser Water Temperature. AI’s have 10 bit A/D resolution. 4 binary inputs: Stage 1 Compressor Status, Condensate Overflow, Fire/Smoke Detector, and Fan Status (optional) |

| Outputs | 2 analog outputs: 1 dedicated to Outside Air Damper, and 1 configurable for either Auxiliary

Reheat or Waterside Economizer. AO’s have 10 bit D/A resolution. 8 binary outputs: Supply Fan (low, medium, and high), Compressor Stage 1, Compressor Stage 2, Reversing Valve, Auxiliary Heat/2-position Waterside Economizer, and Dehumidification. Relay contacts rated at 3A max @ 24VAC, configured normally open |

| Real Time Clock | Battery-backed real time clock keeps track of time in event of power failure |

| Battery | 10-year Lithium CR2032 battery provides a minimum of 10,000 hours of trend data & time retention during power outages |

| Protection | Incoming power and network connections are protected by non-replaceable internal solid-state polyswitches that reset themselves when the condition that causes a fault returns to normal. The power, network, input, and output connections are also protected against voltage transient and surge events. |

| Status Indicators | LED status indicators for network communications, run status, error, power, and all digital outputs |

| Controller Addressing | Rotary dip switches set BACnet MS/TP, Modbus, or N2 address of controller |

| Listed by | UL-873, FCC Part 15-Subpart B-Class A, CE EN50082-1997 |

| Environmental Operating Range | Operating: -40 to 158ºF (-40 to 70ºC)

10 to 95% RH, non-condensing Storage: -40 to 158ºF (-40 to 70ºC) 10 to 95% RH, non-condensing |

| Power Requirements | 24VAC +/- 10%, 50-60Hz, 14 VA power consumption, 26VDC (25V min, 30V max), single class 2 source only, 100 VA or less |