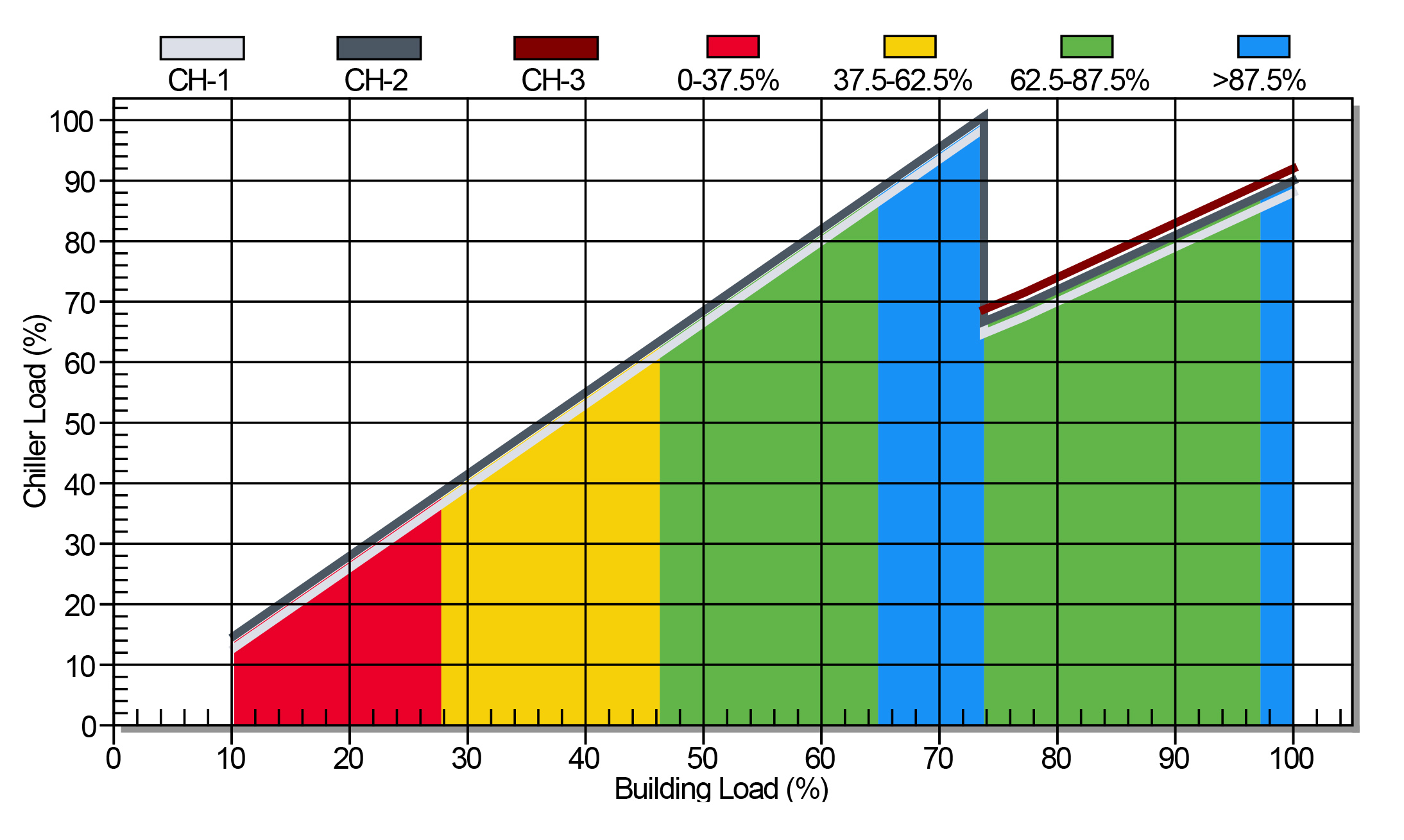

TV Studio, Museum or Library

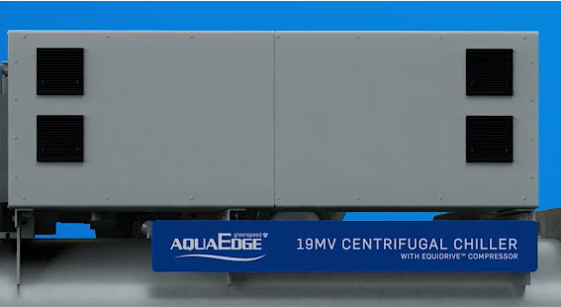

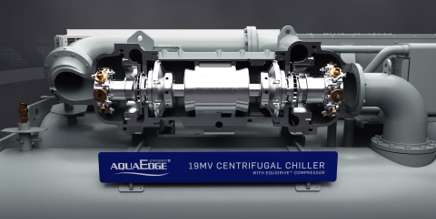

The all-new AquaEdge® 19MV chiller combines best-in-segment efficiency at design and off-design conditions with the ability to operate reliably, even at severe conditions and heavy cooling loads.

Click on a scenario below to learn more about how the 19MV handles different types of building load/weather conditions.