i-Vu® for Data Centers

The i-Vu BAS helps ensure precise environmental conditions in your data center, contributing to consistent server uptime. Its support for open protocols and seamless integration to Carrier HVAC equipment enables centralized monitoring of HVAC systems, switchgear, generators, and more.

Carrier is uniquely positioned to help address your data center challenges:

- MANAGE ENVIRONMENTAL CONDITIONS: Precise climate control is essential to ensure server uptime. Our i-Vu® system precisely controls temperature and humidity in data center environments.

- INCREASE UPTIME & RELIABILITY: Prevent equipment failures and minimize downtime with proactive monitoring and alerts that enable quick action to address potential issues.

- IMPROVE OPERATIONAL EFFICIENCY: Streamline building operations with centralized control and automation. i-Vu provides a single platform to manage all building systems in your data center for end-to-end visibility and remote management.

- DRIVE SUSTAINABILITY MEASURES: Data centers must adopt sustainability practices to reduce energy consumption and achieve net-zero carbon footprints. Our Carrier Controls Experts will work with you to create the right control system design and strategies.

- STAY SECURE: Our i-Vu software is backed by the Carrier Global Cybersecurity Program and undergoes rigorous testing to mitigate and protect it from vulnerabilities at every stage of the lifecycle.

COMPREHENSIVE DATA CENTER SOLUTIONS

Our data center solutions help you improve visibility, control, and efficiency

- HVAC Equipment

- Building Automation & HVAC Controls

- Environmental Monitoring & Control

- Analytics & Fault Detection (FDD)

- Critical Alarming

- Data Visualization

- Predictive Analytics

- PUE Management

- System Redundancy

- Systems Integration

- Integration of Facility and IT Systems (Integrated Data Center Management)

HVAC SOLUTIONS FOR DATA CENTERS

Experience industry-leading efficiency, uptime and dependability with our highly adaptable and easy-to-install air-cooled chiller. Available with waterside economizer for optimized performance and uptime.

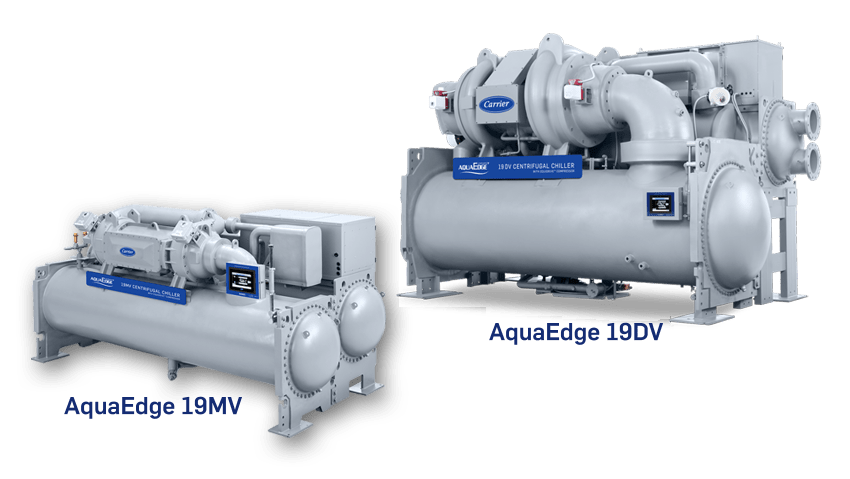

Fast restarts following power loss. Superior performance at higher loads. Our water-cooled chillers deliver the innovative features and exceptional versatility needed to meet the demands of today’s data centers.

Meet the precise requirements of your data center with our custom and semi-custom air handling units that can be optimized with a variety of filters, fans and factory-installed controls for efficient airflow and ventilation.

i-Vu’s intuitive software makes it easy to manage equipment, systems, and facilities from anywhere. It offers guided insights, trend analysis, alarms, thermographic color floor plan displays, intuitive dashboards, and more. Best of all, you can tailor the deployment of your building automation server according to your data center's specific needs.

- i-Vu server software comes preinstalled on a compact appliance

- Supports up to 750 controllers

- Automatic software updates

- Software only; i-Vu server sold separately

- Unlimited simultaneous users

- Available in 5 different software versions to accommodate different project sizes

- i-Vu server software is cloudhosted, reducing your support burden

- BACnet Secure Connect (BACnet/SC), keeps on-premise building automation networks secure

- Automatic software updates and database backups

Our smart controls help you maintain precise control of your data center environment while helping you meet sustainability goals. They also help ensure seamless integration to other critical data center systems for comprehensive monitoring and control through a single user interface.

FLEXIBLE INSTALLATION: Can be factory or field-installed on your HVAC equipment. Application-specific control sequences help ensure optimized equipment operation.

OPEN STANDARDS: Native BACnet communication and BACnet Testing Laboratories (BTL) certification for easy integration with other data center equipment and systems.

INDUSTRY STANDARDS: Supports ASHRAE Guideline 36 and Fault Detection and Diagnostics (FDD) to help data centers optimize energy and proactively address potential equipment issues.

VERSATILE: Support diverse HVAC needs for precise control over your data center environment.

EXTENSIVE LIBRARY: Pre-built sequences for common data center applications, simplifying setup and installation.

CUSTOMIZABLE: Graphical programming allows for tailoring to your unique data center needs.

CHILLERVU™ PLANT CONTROL: Coordinates and optimizes chiller plant operations including chillers, pumps, cooling towers — for maximum efficiency in your data center, helping to reduce energy costs while ensuring a reliable source of chilled water for critical IT equipment.

CHILLED WATER SYSTEM OPTIMIZER: Improves the efficiency of the chilled water system for the data center, including air handling units, fan coils and other distribution equipment. By optimizing chilled water flow and temperature, this technology helps reduce energy consumption, contributing to lower operating costs and a smaller environmental footprint.

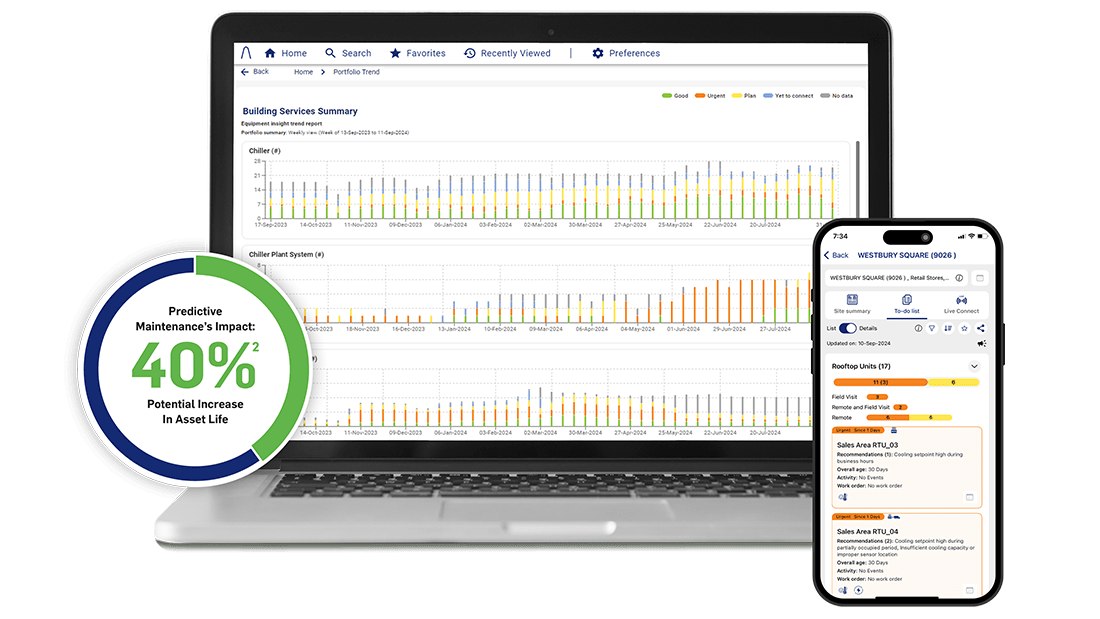

Enhance your i-Vu building automation system with tools that help data center operators gain predictive insights into HVAC equipment performance.

Manage facility and IT systems holistically by integrating your i-Vu system with Nlyte’s data center management software. This Integrated Data Center Management (IDCM) solution helps to increase energy savings, reduce costs and ensure uptime.

SUCCESS STORIES

A large scale data center in Shanghai, China turned to Carrier to help optimize their cooling system efficiency. The solution featured eight Carrier 19XR chillers and two i-Vu® ChillerVu plant control systems, resulting in 23% energy savings for the chillers and an additional 10% with controls. Overall, efficiency improved by over 30%, saving 210,000 kWh annually.

A New Jersey healthcare facility partnered with Carrier to manage their data center using i-Vu Pro software. TruVu controls, integrated via the BACnet protocol, enable centralized monitoring of CRAC units, generators, PDUs, batteries, electric meters, paralleling gear, leak panels, and a UPS.