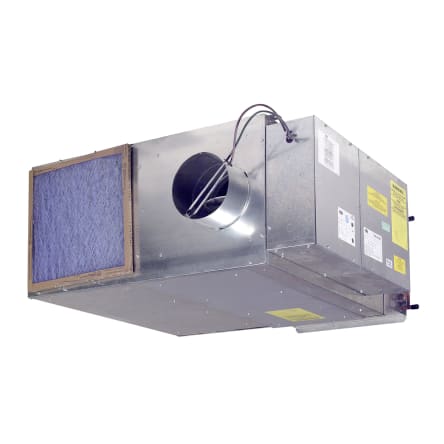

AXIS™ Quiet Series Fan-Powered Terminal

45K

Up to 3,000 Cfm (Primary & Fan Airflow)

The 45K fan-powered units provide a combination of primary air cooling or plenum induction and reheat to meet most application needs at the lowest possible sound levels.

Performance Features

- Fan airflow capacities from 50 to 3000 CFM

- Primary airflow capacities from 52 to 3000 CFM

- Ultra quiet operation for critical sound applications

- Round inlet sizes from 6 in. through 16 in. diameter

- 20 gage, galvanized steel casing construction

- Integral induced air sound attenuator

- Suitable for low, medium, or high pressure applications

- Linear, multiple-point, averaging velocity sensor with an amplified signal

- Damper blade has a flexible gasket for tight airflow shutoff

- Damper blade operates over a full 90 degrees

- All damper assemblies utilize a solid ½ in. shaft that rotates in self-lubricating Delrin® bearings

- Pressure independent controls, including Carrier i-Vu Open (BACnet), Carrier Comfort Network® (CCN), analog, or pneumatic controls

- Electric or hot water reheat coils

- Multiple casing liners available

- Electric heat (1 to 3 stages) or proportional (SSR) heat

- Standard unit casing lined with ½ in. thick, 1-1/2 lb dual density fiberglass insulation that meets UL 181 and NFPA 90A

- Certified performance in accordance with ARI Standard 880

Reliability Features

- 20 gage, galvanized steel heaters are ETL listed in accordance with UL standards

- Heaters equipped with:

- Primary automatic and secondary manual reset thermal cutout

- Deenergizing magnetic contactors

- Airflow proving switch

- 80/20 Ni-Cr elements

- Strong integral panel/post construction for product durability

Maintenance Features

- NEMA 2 steel control enclosure for electric or electronic components

- Removable bottom access panel for easy accessibility during routine inspections and maintenance

- Label information adhered to each unit includes model, size, airflow (cfm), balancing chart, and tagging data

Installation Features

- Rectangular discharge with slip and drive connections provides quick and easy connection to downstream ductwork

- Compact unit casing accommodates installation in reduced ceiling plenum space

- Factory-installed controls

- All round collars accommodate standard spiral and flex duct sizes

- Balancing taps provided for easy airflow verification

- Single point electrical connection

Standard Warranty

- One-year parts

Factory-Installed Options

- Control options:

- Analog electronic controls

- Carrier i-Vu Open VAV Controls

- Carrier Comfort Network (CCN) VAV Controls

- Pneumatic controls

- No controls or field-supplied DDC (direct digital controls) third party controls

- Left-hand or right-hand control enclosure (dust-tight)

- Hanger brackets

- Hot water coils (1 or 2 rows)

- Liner options:

- 1 in. thick, dual density fiberglass

- Cellular

- Steriliner (foil-faced duct board)

- Sterilwall (double wall)

- Foil encapsulated fiberglass

- Perforated double wall

- None

- Vent and drain on water coils

- Electric heat (1 to 3 stages)

- Proportional SSR (solid-state relays) electric heat

- Electric heater options:

- Fused door interlocking disconnect switch

- Non-fused door interlocking disconnect switch

- Mercury contactors

- Fuse block with fuses for primary overload protection

- Dust-tight construction

- Motor fusing

- Recirculated air filter

- ECM (electronically commutated motor) motors

Field-Installed Accessories

- Remote wall sensor

- Supply-air temperature sensor

- CO2 sensor

Performance Features

- Fan airflow capacities from 50 to 3000 CFM

- Primary airflow capacities from 52 to 3000 CFM

- Ultra quiet operation for critical sound applications

- Round inlet sizes from 6 in. through 16 in. diameter

- 20 gage, galvanized steel casing construction

- Integral induced air sound attenuator

- Suitable for low, medium, or high pressure applications

- Linear, multiple-point, averaging velocity sensor with an amplified signal

- Damper blade has a flexible gasket for tight airflow shutoff

- Damper blade operates over a full 90 degrees

- All damper assemblies utilize a solid ½ in. shaft that rotates in self-lubricating Delrin® bearings

- Pressure independent controls, including Carrier i-Vu Open (BACnet), Carrier Comfort Network® (CCN), analog, or pneumatic controls

- Electric or hot water reheat coils

- Multiple casing liners available

- Electric heat (1 to 3 stages) or proportional (SSR) heat

- Standard unit casing lined with ½ in. thick, 1-1/2 lb dual density fiberglass insulation that meets UL 181 and NFPA 90A

- Certified performance in accordance with ARI Standard 880

Reliability Features

- 20 gage, galvanized steel heaters are ETL listed in accordance with UL standards

- Heaters equipped with:

- Primary automatic and secondary manual reset thermal cutout

- Deenergizing magnetic contactors

- Airflow proving switch

- 80/20 Ni-Cr elements

- Strong integral panel/post construction for product durability

Maintenance Features

- NEMA 2 steel control enclosure for electric or electronic components

- Removable bottom access panel for easy accessibility during routine inspections and maintenance

- Label information adhered to each unit includes model, size, airflow (cfm), balancing chart, and tagging data

Installation Features

- Rectangular discharge with slip and drive connections provides quick and easy connection to downstream ductwork

- Compact unit casing accommodates installation in reduced ceiling plenum space

- Factory-installed controls

- All round collars accommodate standard spiral and flex duct sizes

- Balancing taps provided for easy airflow verification

- Single point electrical connection

Standard Warranty

- One-year parts

Factory-Installed Options

- Control options:

- Analog electronic controls

- Carrier i-Vu Open VAV Controls

- Carrier Comfort Network (CCN) VAV Controls

- Pneumatic controls

- No controls or field-supplied DDC (direct digital controls) third party controls

- Left-hand or right-hand control enclosure (dust-tight)

- Hanger brackets

- Hot water coils (1 or 2 rows)

- Liner options:

- 1 in. thick, dual density fiberglass

- Cellular

- Steriliner (foil-faced duct board)

- Sterilwall (double wall)

- Foil encapsulated fiberglass

- Perforated double wall

- None

- Vent and drain on water coils

- Electric heat (1 to 3 stages)

- Proportional SSR (solid-state relays) electric heat

- Electric heater options:

- Fused door interlocking disconnect switch

- Non-fused door interlocking disconnect switch

- Mercury contactors

- Fuse block with fuses for primary overload protection

- Dust-tight construction

- Motor fusing

- Recirculated air filter

- ECM (electronically commutated motor) motors

Field-Installed Accessories

- Remote wall sensor

- Supply-air temperature sensor

- CO2 sensor

California residents please see Proposition 65