Leicestershire Farming Company

Project description

A Leicestershire farming company has installed a combined 8 megawatts (MW) of high-efficiency Carrier AquaForce® ground-source heat pumps in two projects to increase the quality of hay production and enhance returns.

Welland Farm was inspired by a previous project carried out by OMNI Heat and Power Ltd in which the renewable energy specialist selected Carrier ground-source heat pumps to provide a controlled environment for drying premium quality hay for racehorses.

With its higher efficiency, the Carrier solution uses less power and costs less to run than other options, with a Coefficient of Performance (CoP) of 5.24. Alternative options considered required the use of heat pumps based on up to 80 compressors to achieve the desired output to dry the hay.

Background

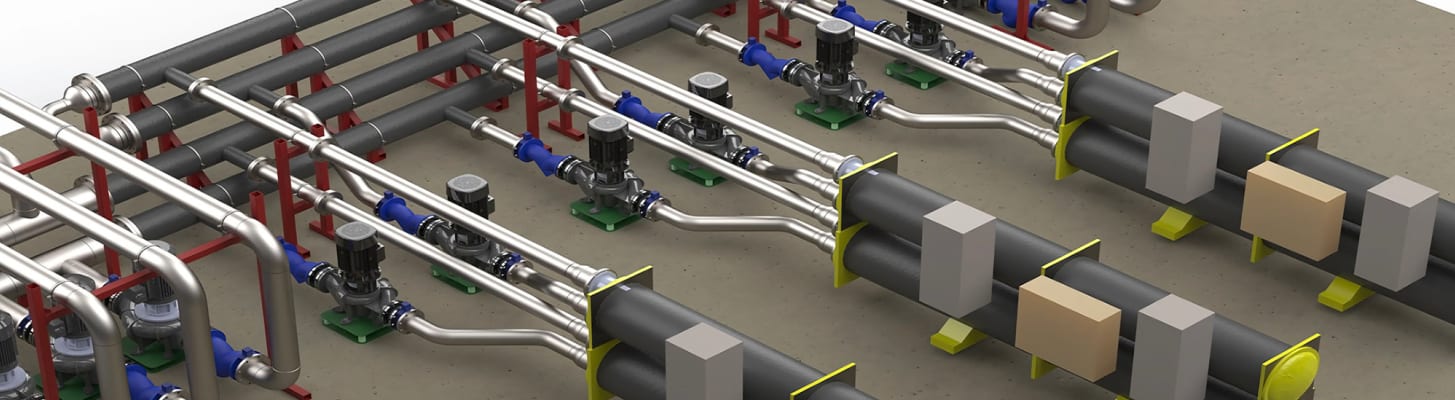

The systems use an array of pipes buried in trenches for gathering energy from the ground, each with a total pipe length of some 24 kilometres. Once the heat pumps have upgraded the energy collected, it is transferred to air handling units serving the crop drying rooms.

AquaForce heat pumps are Carrier’s premium solution for commercial and industrial applications where end users require maximum quality and optimal performance, especially at part load. They deliver outstanding energy efficiency, excellent reliability, low sound levels and, for contractors, rapid installation and commissioning on-site.

- Outstanding energy efficiency

- Less-expensive-to-run

- Excellent reliability

- Low sound levels

- Rapid installation and commissioning on-site

- 3 x Carrier AquaForce® Ground-source Heat Pumps

“Due to their higher capacity, the Carrier solution required just three heat pumps based on a total of six compressors,” said Bradley Martin, Director of OMNI Heat and Power. “This simplifies maintenance and significantly reduces servicing costs for the end user over the lifetime of the equipment.”

“The quicker hay can be dried, the greater the yield, and the greater the return for the producer,” said Bradley Martin. “Traditional methods following harvesting involve leaving bales in the fields to dry naturally, which can result in significant losses due to spoilage in wet conditions. Bringing the crop inside and drying it in a controlled environment results in higher quality and minimises losses.”