IdroFan® - Coanda effect cassette

42KY

Cooling capacity : 1.2-5 kW

Heating capacity : 1.7-6 kW

Energy performance, comfort and indoor air quality: Carrier's new 42KY cassette is the all-in-one solution to meet heating and cooling requirements for commercial buildings and provide optimum comfort for users.

- Optimized Coanda Effect diffusion

- Indoor comfort

- Air quality

- Responsiveness of the system and individual adjustment

- Low energy consumption

- Acoustic comfort

- Design

- Ease of maintenance

This cassette is a 600 x 600 mm format existing in 3 sizes and available in:

- 2 pipe, for heating and/or cooling mode

- 2 pipe + electrical heater, for heating and/or cooling + electrical mode

- 4 pipe, for cooling and heating mode

Innovative design

- Next generation chassis that combines high density EPS for its thermal and phonic properties, ABS PC and a ribbed galvanized sheet steel base to stiffen the assembly

- Chassis with unique dimensions for all sizes, adapted to the suspended ceiling grid size 600 x 600 mm

- Hydraulic, air and electrical connections on the same side to facilitate installation and access for maintenance operations

Design for comfort & energy optimization

- Greater comfort

- Optimized Coanda Effect diffusion for perfect control of thermal phenomena that can cause discomfort and make the room feel draughty

- Anti-cold shower effect

- Compliance with energy requirements

- Specially developed temperature exchange coils to meet the requirements of low energy buildings

- Optimized temperature exchange coils to limit cost and consumption in comparison with the other components of the installation

- LEC low consumption motor

- Reduction in power of the electric heating coils to match the requirements of new buildings

Ease of installation and operation

- Designed to be easy to fit and not require many on-site operations

- Optimized weight and size to facilitate handing during installation

- Safety system to suspend the diffuser leaving the technician's hands free to tighten the mounting bolts

- Access to internal components without the need to open suspended ceilings, easy to open filter hatch grille that is hinged to facilitate maintenance operations

- Diffusion panels supplied in individual packaging, making it easier to fit the unit with no risk of damaging or soiling visible parts during installation

Eco-design

- Raw materials : 30% saving in weight and 21% saving in volume thanks to a compact and well thought out architecture. Use of easily recyclable materials (EPS and ABS)

- Transport : raw material suppliers selected from those that are less than 100 km from our manufacturing and packaging factory, enabling a 50% gain in volumes transported (reduction in CO² emissions)

- Recycling and easy of disassembly : 90% recyclable products. Materials can be completely separated and fixings have been reduced by 40% to allow greater efficiency at recycling plants

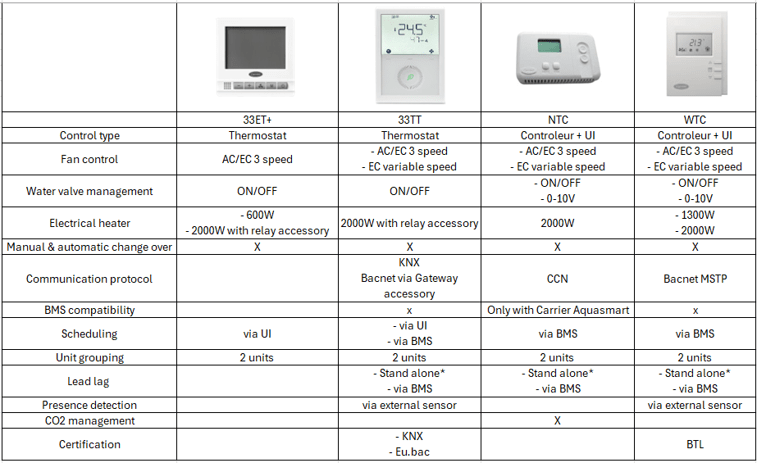

This table provides a quick and easy overview of the key features of our products. To learn more about them and make the best choice, consult their detailed product sheet.

*Stand alone : Lead/lag configurable via the device for the application once the KNX bus is connected. BMS not required in this case.

This cassette is a 600 x 600 mm format existing in 3 sizes and available in:

- 2 pipe, for heating and/or cooling mode

- 2 pipe + electrical heater, for heating and/or cooling + electrical mode

- 4 pipe, for cooling and heating mode

Innovative design

- Next generation chassis that combines high density EPS for its thermal and phonic properties, ABS PC and a ribbed galvanized sheet steel base to stiffen the assembly

- Chassis with unique dimensions for all sizes, adapted to the suspended ceiling grid size 600 x 600 mm

- Hydraulic, air and electrical connections on the same side to facilitate installation and access for maintenance operations

Design for comfort & energy optimization

- Greater comfort

- Optimized Coanda Effect diffusion for perfect control of thermal phenomena that can cause discomfort and make the room feel draughty

- Anti-cold shower effect

- Compliance with energy requirements

- Specially developed temperature exchange coils to meet the requirements of low energy buildings

- Optimized temperature exchange coils to limit cost and consumption in comparison with the other components of the installation

- LEC low consumption motor

- Reduction in power of the electric heating coils to match the requirements of new buildings

Ease of installation and operation

- Designed to be easy to fit and not require many on-site operations

- Optimized weight and size to facilitate handing during installation

- Safety system to suspend the diffuser leaving the technician's hands free to tighten the mounting bolts

- Access to internal components without the need to open suspended ceilings, easy to open filter hatch grille that is hinged to facilitate maintenance operations

- Diffusion panels supplied in individual packaging, making it easier to fit the unit with no risk of damaging or soiling visible parts during installation

Eco-design

- Raw materials : 30% saving in weight and 21% saving in volume thanks to a compact and well thought out architecture. Use of easily recyclable materials (EPS and ABS)

- Transport : raw material suppliers selected from those that are less than 100 km from our manufacturing and packaging factory, enabling a 50% gain in volumes transported (reduction in CO² emissions)

- Recycling and easy of disassembly : 90% recyclable products. Materials can be completely separated and fixings have been reduced by 40% to allow greater efficiency at recycling plants

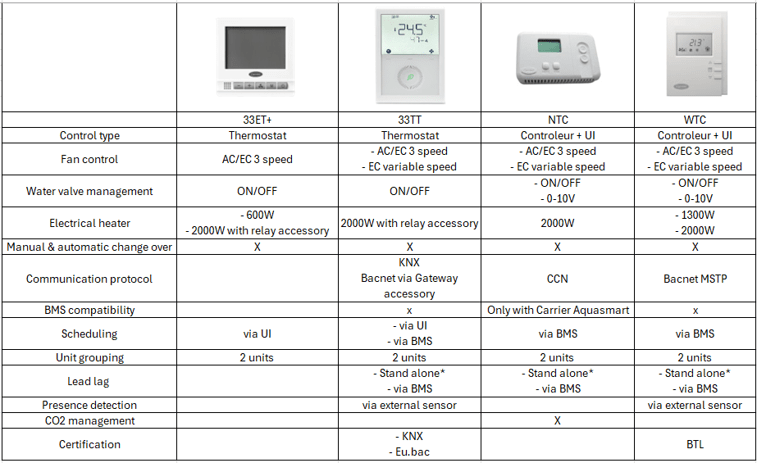

This table provides a quick and easy overview of the key features of our products. To learn more about them and make the best choice, consult their detailed product sheet.

*Stand alone : Lead/lag configurable via the device for the application once the KNX bus is connected. BMS not required in this case.