AquaSnap® - Air-cooled liquid scroll chiller

30RBS

Refrigerant : R-410A

Compressor : scroll fixed-speed

Nominal cooling capacity : 40-160 kW

The AquaSnap range of liquid chillers was designed for commercial (air conditioning of offices, hotels etc.) or industrial (low-temperature process units etc.) applications.

- Commercial and industrial applications

- Compact design

- Quiet operation

- Variable water flow

- Partial heat reclaim

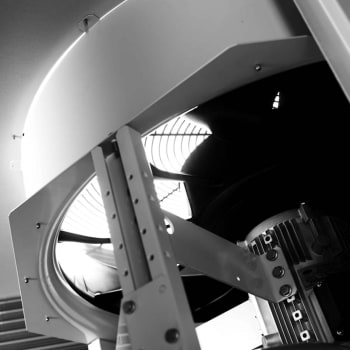

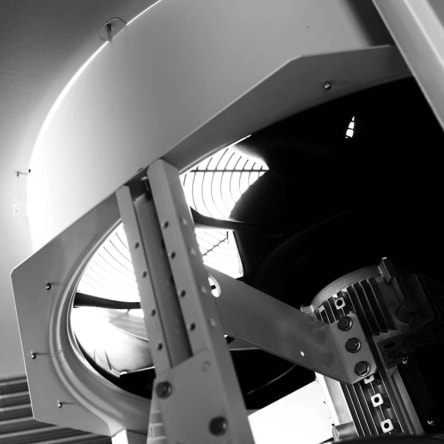

Quiet operation

- Low-noise scroll compressors installed on an independent chassis and supported by anti-vibration mountings

- Vertical condenser coils

- Low-noise 4th generation Flying Bird™ IV fans, made of a composite material

Easy and fast installation

- Integrated hydraulic module (option)

- Small footprint and a low height

- Easily removable panels

- Simplified electrical connections

- Fast commissioning

Economical operation

- Increased energy efficiency at part load

- Reduced maintenance costs

- Variable-speed pump (option)

Environmental care

- Non-ozone depleting refrigerant R-410A

- Leak-tight refrigerant circuit

Superior reliability

- State-of-the-art concept

- Auto-adaptive control

- Exceptional endurance tests

Novation® Aluminum micro-channel heat exchangers

- Novation® microchannel coils technology

- Extra-resistant aluminum alloy

- Corrosion resistance

- Can be used in moderate marine and urban environments

- Approximately 10% more efficient than a traditional coil

- 40% reduction in the amount of refrigerant used in the chiller

- Reduces air pressure losses by 50%

- Can be cleaned very quickly

SmartVu™ control

- Energy management

- Internal time schedule clock

- Set-point offset based on the outside air temperature

- Lead/lag control of two heat pumps operating in parallel

- Maintenance

- Tendencies Curve Display

- Maintenance and Control Reminder

- Storage of user documents, electrical diagrams and spare parts

- Last 50 defects in memory with values of all machine parameters

- Integrated advances communication features

- Night mode

- Easy and high-speed communication technology over Ethernet (IP) to a building management system

- Storage of user documents, electrical diagrams and spare parts

- Access to multiple unit parameters

- User friendly and intuitive 4.3" color touch screen user interface

Remote management (standard)

- Easily accessed from the internet

- Multiple remote control, monitoring and diagnostic possibilities

- Optional communication gateways

- Start/Stop of the machine

- Dual set-point management

- Water pump control

- Coils Corrosion Protection

- Medium or low temperature brine solution

- Winter operation down to -20°C

- Partial heat recovery

- Very low noise level

- Grilles and enclosure panels

- Hydraulic module with choice of pump

- Water buffer tank module

- Expansion tank

- Frost protection

- Lon, J-Bus or BacNet gateway

- Lead/lag operation

- Free cooling DryCooler Management

- Main disconnect switch without fuse

- Soft starter

- Reinforced EMC filtration

- Compliance with Russian regulations

- Welded exchangers connection kit

Quiet operation

- Low-noise scroll compressors installed on an independent chassis and supported by anti-vibration mountings

- Vertical condenser coils

- Low-noise 4th generation Flying Bird™ IV fans, made of a composite material

Easy and fast installation

- Integrated hydraulic module (option)

- Small footprint and a low height

- Easily removable panels

- Simplified electrical connections

- Fast commissioning

Economical operation

- Increased energy efficiency at part load

- Reduced maintenance costs

- Variable-speed pump (option)

Environmental care

- Non-ozone depleting refrigerant R-410A

- Leak-tight refrigerant circuit

Superior reliability

- State-of-the-art concept

- Auto-adaptive control

- Exceptional endurance tests

Novation® Aluminum micro-channel heat exchangers

- Novation® microchannel coils technology

- Extra-resistant aluminum alloy

- Corrosion resistance

- Can be used in moderate marine and urban environments

- Approximately 10% more efficient than a traditional coil

- 40% reduction in the amount of refrigerant used in the chiller

- Reduces air pressure losses by 50%

- Can be cleaned very quickly

SmartVu™ control

- Energy management

- Internal time schedule clock

- Set-point offset based on the outside air temperature

- Lead/lag control of two heat pumps operating in parallel

- Maintenance

- Tendencies Curve Display

- Maintenance and Control Reminder

- Storage of user documents, electrical diagrams and spare parts

- Last 50 defects in memory with values of all machine parameters

- Integrated advances communication features

- Night mode

- Easy and high-speed communication technology over Ethernet (IP) to a building management system

- Storage of user documents, electrical diagrams and spare parts

- Access to multiple unit parameters

- User friendly and intuitive 4.3" color touch screen user interface

Remote management (standard)

- Easily accessed from the internet

- Multiple remote control, monitoring and diagnostic possibilities

- Optional communication gateways

- Start/Stop of the machine

- Dual set-point management

- Water pump control

- Coils Corrosion Protection

- Medium or low temperature brine solution

- Winter operation down to -20°C

- Partial heat recovery

- Very low noise level

- Grilles and enclosure panels

- Hydraulic module with choice of pump

- Water buffer tank module

- Expansion tank

- Frost protection

- Lon, J-Bus or BacNet gateway

- Lead/lag operation

- Free cooling DryCooler Management

- Main disconnect switch without fuse

- Soft starter

- Reinforced EMC filtration

- Compliance with Russian regulations

- Welded exchangers connection kit

Documents