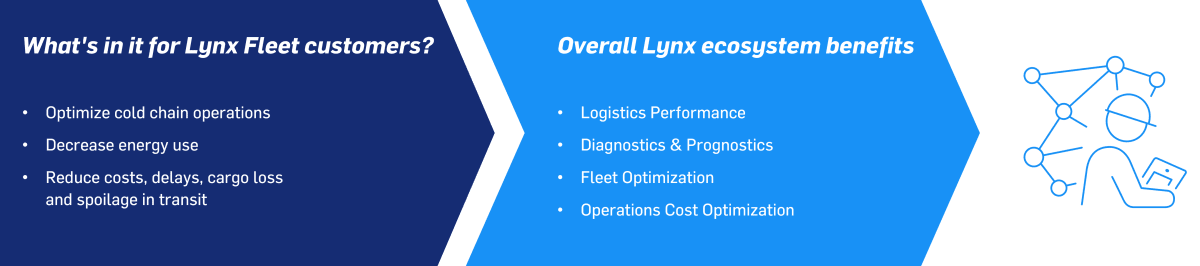

Lynx Fleet open ecosystem will intelligently monitor connected refrigeration systems from anywhere in the world, providing vital information for producers, drivers, transport managers and retailers on the products being transported and the vehicles transporting them. The digital system will provide access to live service for each connected refrigeration unit, helping to aid fleet management procedures and ensure minimal disruption through vehicle downtime. It can be customized to meet customer needs and will continue to evolve.

The new Lynx Fleet software offers operators 24/7 access to a wealth of valuable data on their refrigeration systems, including but not limited to advanced remote temperature monitoring, two-way operational management and control capability, in-depth service and utilization reports, geo-fencing, operational alarms.