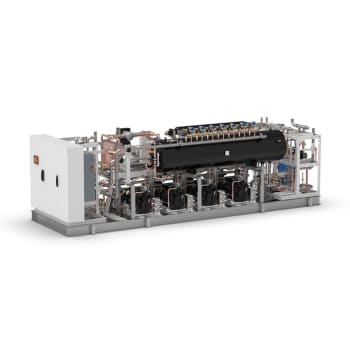

PowerCO2OL™ Indoor/Outdoor

Industrial CO2 transcritical solution

BENEFITS AT A GLANCE

- Uses CO2 natural refrigerant

- Modulating vapor ejector

- Single or dual evaporating temperature

- Heat & recovery and air conditioning (Option)

Industrial CO2 transcritical solution

Key Features

- Uses CO2 natural refrigerant

- Not affected by the EU F-Gas Regulation

- Single or dual evaporating temperature

- Chiller version

- Optional outdoor frame for outdoor installation

- Semi-hermetic compressors (6 cylinders)

- Integrated controls (rack and gas cooler)

- Designed for / Heat pump, Sport venue, distribution center, food processing, Ice rink, Large food retail, A/C, Tunnel freezer

- Inverter on the main compressor (MT and LT as standard)

- Modulating vapor ejector

- Heat & recovery and air conditioning (Option)

- Numerous options available

- Service pressure:

- Suction LT: 80 Bar (Optional 60 Bar)

- Suction MT: 80 Bar (Optional 60 Bar)

- Liquid receiver: 80 Bar

- Gas cooler discharge: 120 Bar (Optional 130 Bar)

NB of compressors

- 3-8 (MT)

- 3-6 (LT)

Cooling capacity

- Up to 1500 kW (MT), Up to 550 kW (LT)

- -10°C / +36°C ambient air temperature (negative heat rejection not deducted)

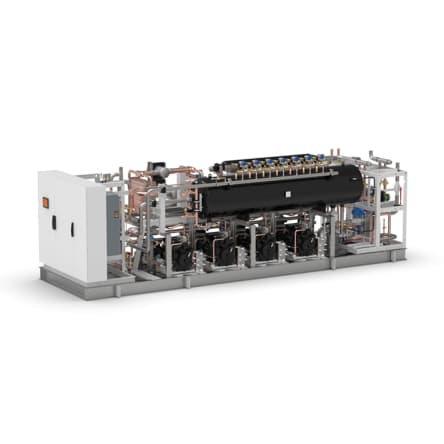

Industrial CO2 transcritical solution

Key Features

- Uses CO2 natural refrigerant

- Not affected by the EU F-Gas Regulation

- Single or dual evaporating temperature

- Chiller version

- Optional outdoor frame for outdoor installation

- Semi-hermetic compressors (6 cylinders)

- Integrated controls (rack and gas cooler)

- Designed for / Heat pump, Sport venue, distribution center, food processing, Ice rink, Large food retail, A/C, Tunnel freezer

- Inverter on the main compressor (MT and LT as standard)

- Modulating vapor ejector

- Heat & recovery and air conditioning (Option)

- Numerous options available

- Service pressure:

- Suction LT: 80 Bar (Optional 60 Bar)

- Suction MT: 80 Bar (Optional 60 Bar)

- Liquid receiver: 80 Bar

- Gas cooler discharge: 120 Bar (Optional 130 Bar)

NB of compressors

- 3-8 (MT)

- 3-6 (LT)

Cooling capacity

- Up to 1500 kW (MT), Up to 550 kW (LT)

- -10°C / +36°C ambient air temperature (negative heat rejection not deducted)

You Might Also Like