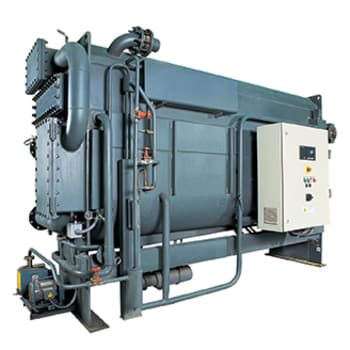

16JL/JLR

Steam / Hot Water Single Effect,

Hermetic Absorption Liquid Chiller

Carrier’s 16JL/JLR steam/hot single effect, hermetic absorption liquid chiller is an efficient and functional alternative to traditional electric driven chillers. By utilizing low pressure steam or low-temperature hot water, 16JL/JLR chillers avoid high-cost electricity and qualify for utility rebates and incentives as a gas cooling product.

16JL: Cooling Capacity: 150 to 1000 Nominal Tons (528 to 3516kW)

16JLR: Cooling Capacity: 110 to 750 Nominal Tons (387 to 2637kW)

The 16JL/JLR absorption chiller offers functional flexibility in a variety of installations:

No CFCs; environmentally friendly

Single stage design for simple, dependable operation

Quiet, vibration-free operation

High reliability with few moving parts

Features

- Nominal full-load steam rate of 16.65 lb/hr-ton for 16JL

- Nominal coefficient of performance (COP) of 0.73 for 16JLR

- The 16JL/JLR’s standard concentration control system allows stable, part-load operation at cooling water temperatures as low as 59 F (15 C) without the need for a cooling tower bypass

- The 16JL/JLR chiller has a continuous operating range from 100% to 10% of rated machine capacity.

- The overall sound level of a Carrier 16JL/JLR is typically 80dbA when measured per Standard ARI Standard 575 (latest edition).

- Chiller performance shall be rated in accordance with ARI Standard 560 (latest edition).

- Chiller shall be manufactured and designed in accordance with ANSI/ASHRAE 15 (latest edition), Safety Code for Mechanical Refrigeration.

- Chiller shall be designed and constructed to meet applicable (GB) requirements.

- Environmentally Sound: Chilled water is produced using water as the refrigerant in place of ozone depleting chlorine-based compounds

- Alternative Energy Use: Uses hot water as primary energy source. Electricity only required for pumps, controls

- Application Flexibility: Hybrid chiller plants allows flexibility and optimization of energy costs

- Cogeneration applications take advantage of waste heat often available in many facilities thus improving overall plant efficiency

- Single-effect absorption cycle provides efficient, economical water chilling and/or process cooling with minimal use of electricity.

- "16JL/JLR single-effect absorption chiller offers versatility for almost any job where low pressure team/low temperature hot water is available as the heat source."

- Each Carrier 16JL/JLR absorption chiller includes a factory mounted and wired microprocessor control center that is functionally tested prior to shipment.

- PD5 provides VFD for solution pump control. The PD5 can be interface with the Carrier Comfort Network (CCN) with additional hardware. The user interface is a touch screen.

- Single-point box electrical connection

- Each chiller shall undergo a series of standard factory tests to ensure that the unit is leak tight, that all electrical components operate as intended.

- "The 16JL/JLR offers an alternative to chillers driven by increasingly expensive electrical energy by use of steam / hot water powered absorption chiller.

- Automatic, motorless purge system extends machine life and ensures optimum efficiency and performance

- Anti-crystallization controls maintain proper solution concentration

- Low sound and vibration levels are characteristic of absorption chillers, primarily due to the fact that the only rotating parts are the refrigerant and solution pumps.

- High Reliability / Low Maintenance Cost: Few moving parts equates to inherent high reliability as well as lower maintenance costs

- Every 16JL/JLR machine has numerous standard design features that are provided for convenient and simple maintenance, reliable and trouble free operation.

- Leak-proof hermetic pumps/motors cut maintenance costs

- Superior corrosion protection -The Carrier 16JL/JLR absorption chiller incorporates a highly effective corrosion inhibitor to provide an extra margin of protection against internal corrosion.

- Automatic, motorless purge system extends machine life and ensures optimum efficiency and performance

- Guarantee of quality by Carrier advanced equipment and workmanship

Features

- Nominal full-load steam rate of 16.65 lb/hr-ton for 16JL

- Nominal coefficient of performance (COP) of 0.73 for 16JLR

- The 16JL/JLR’s standard concentration control system allows stable, part-load operation at cooling water temperatures as low as 59 F (15 C) without the need for a cooling tower bypass

- The 16JL/JLR chiller has a continuous operating range from 100% to 10% of rated machine capacity.

- The overall sound level of a Carrier 16JL/JLR is typically 80dbA when measured per Standard ARI Standard 575 (latest edition).

- Chiller performance shall be rated in accordance with ARI Standard 560 (latest edition).

- Chiller shall be manufactured and designed in accordance with ANSI/ASHRAE 15 (latest edition), Safety Code for Mechanical Refrigeration.

- Chiller shall be designed and constructed to meet applicable (GB) requirements.

- Environmentally Sound: Chilled water is produced using water as the refrigerant in place of ozone depleting chlorine-based compounds

- Alternative Energy Use: Uses hot water as primary energy source. Electricity only required for pumps, controls

- Application Flexibility: Hybrid chiller plants allows flexibility and optimization of energy costs

- Cogeneration applications take advantage of waste heat often available in many facilities thus improving overall plant efficiency

- Single-effect absorption cycle provides efficient, economical water chilling and/or process cooling with minimal use of electricity.

- "16JL/JLR single-effect absorption chiller offers versatility for almost any job where low pressure team/low temperature hot water is available as the heat source."

- Each Carrier 16JL/JLR absorption chiller includes a factory mounted and wired microprocessor control center that is functionally tested prior to shipment.

- PD5 provides VFD for solution pump control. The PD5 can be interface with the Carrier Comfort Network (CCN) with additional hardware. The user interface is a touch screen.

- Single-point box electrical connection

- Each chiller shall undergo a series of standard factory tests to ensure that the unit is leak tight, that all electrical components operate as intended.

- "The 16JL/JLR offers an alternative to chillers driven by increasingly expensive electrical energy by use of steam / hot water powered absorption chiller.

- Automatic, motorless purge system extends machine life and ensures optimum efficiency and performance

- Anti-crystallization controls maintain proper solution concentration

- Low sound and vibration levels are characteristic of absorption chillers, primarily due to the fact that the only rotating parts are the refrigerant and solution pumps.

- High Reliability / Low Maintenance Cost: Few moving parts equates to inherent high reliability as well as lower maintenance costs

- Every 16JL/JLR machine has numerous standard design features that are provided for convenient and simple maintenance, reliable and trouble free operation.

- Leak-proof hermetic pumps/motors cut maintenance costs

- Superior corrosion protection -The Carrier 16JL/JLR absorption chiller incorporates a highly effective corrosion inhibitor to provide an extra margin of protection against internal corrosion.

- Automatic, motorless purge system extends machine life and ensures optimum efficiency and performance

- Guarantee of quality by Carrier advanced equipment and workmanship