Keeping Water Warm

As swimmers shattered world records in the pool at the National Aquatic Center in Beijing, innovative Carrier technology was putting on an amazing performance of its own.

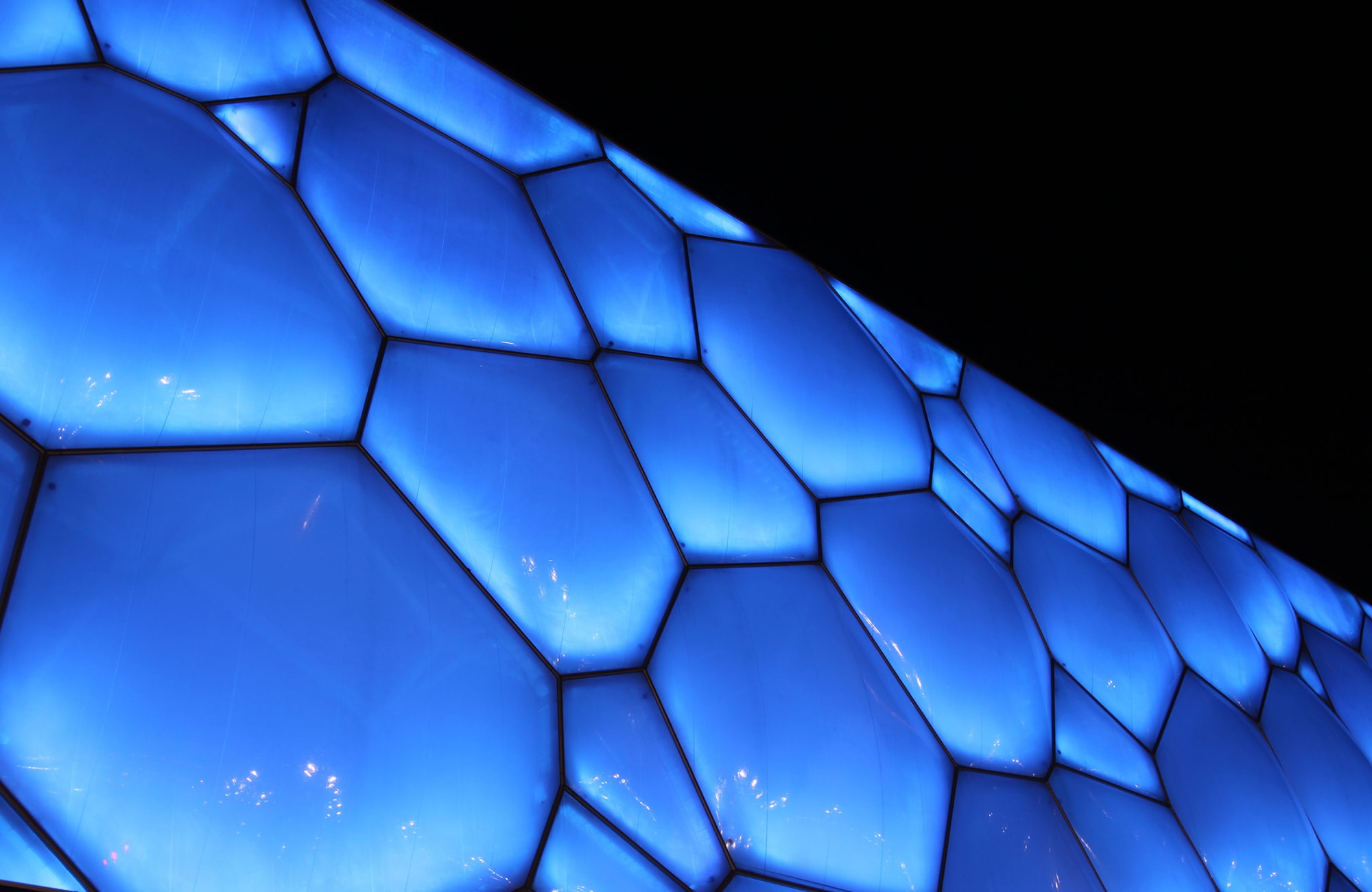

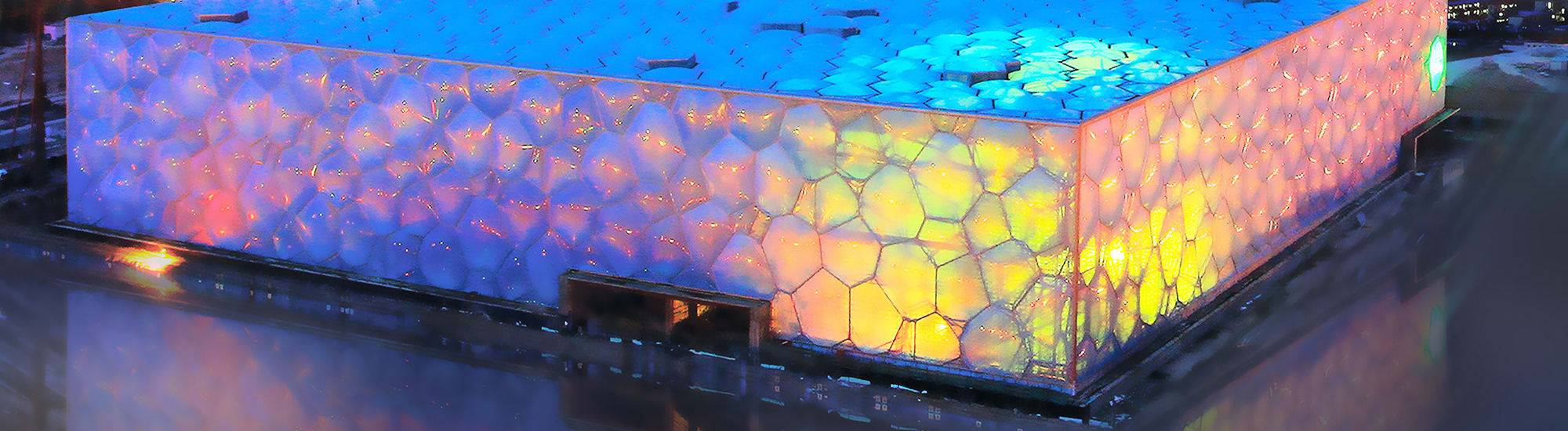

In 2008, spectators and television audiences worldwide watched in awe as international athletes shattered world records, winning gold medal after gold medal in the waters of the National Aquatic Center in Beijing, China. As the unprecedented events transpired in the pool at the “Water Cube,” something else rather amazing was taking place.

Carrier® technology was at work heating the water with repurposed energy. Four Carrier® centrifugal chillers recovered more than 50 percent of the exhaust heat from the building’s air conditioning systems and used it to heat the water for the world’s fastest swimmers.

The Water Cube is not the only place where Carrier is turning green into gold. In factories, where workers require contrasting conditions for manufacturing, and hotels, where guests expect both cool air and hot showers, heating is often required in one part of the building while cooling is simultaneously required in another. A Carrier® heat recovery chiller transfers unwanted heat from the building’s cooling system into the hot water system, saving energy and reducing emissions compared to traditional boilers.

By harnessing previously discarded heat energy, this innovative Carrier technology can be used as an alternative to burning fossil fuels to create hot water. Carrier® heat recovery chillers help buildings achieve greater energy efficiency, use fewer natural resources and save money over natural gas, electric and fuel oil boilers. Freshwater consumption and chemical treatment requirements are also reduced, as the unwanted heat is transferred to the hot water loop instead of being directed outdoors.

Carrier puts this concept to use not only in customers’ buildings, but in our own factories as well. Our Charlotte, North Carolina, manufacturing plant, the 10th building in the world to receive the Leadership in Energy and Environmental Design (LEED®) for Existing Buildings green building rating from the U.S. Green Building Council®, has reduced its natural gas bill by implementing a heat recovery chiller system.

Whether it is for world-class swimmers, hotel guests, factory workers or other users of commercial buildings, Carrier can always be counted on to deliver warm water innovation in a method that is worthy of a gold medal in efficiency and environmental responsibility.

LEED® and U.S. Green Building Council® are registered trademarks owned by the U.S. Green Building Council.