Process Cooling - 5,700kW Cooling Tower Hire -

Midlands

The Challenge

This specialist manufacturer of aircraft brake linings was experiencing interruptions to production as a result of poor temperature control of process cooling water. The end user required an urgent temporary solution to maintain production and product quality of these critical, high value components while it developed a long-term solution.

What Did We Do?

Our experienced team attended site and carried out a survey to assess the cooling requirement and survey conditions for location of temporary cooling towers. Chilled water was required to cool the ovens used to bake brake linings. The required water temperature was 22°C but was currently running at 35°C.

This posed a major problem, as the plant had an automatic cut-off at 36°C to protect the quality of the finished product, resulting in frequent trip-outs and loss of production. A proposal for a temporary solution was put forward and accepted by the end user.

How Did We Do It?

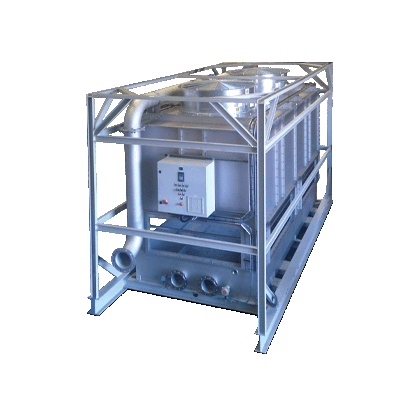

CRS installed a scaffold-supported platform on which to mount three brand new 1.9mW evaporative cooling towers adjacent to the site’s existing process cooling water reservoir. We also commissioned the manufacture of a steel manifold to feed return water from the plant into the cooling towers.

End User – Manufacturer of critical aircraft components

Application – Aeronautical engineering

Equipment – 3 x KwikTOWER CT1900 cooling towers

Accessories – 8in chilled water hose, cables, manifold, scaffold platform

Manufacturing

Process Cooling

Midlands

5,700kW Cooling

Tower Hire

Once commissioned and connected, the CRS cooling towers were quickly brought online, allowing the client to resume production without interruption.

The hire solution is expected to remain in place for 26 weeks, providing the client with ample time to evaluate long-term options and determine a permanent cooling strategy.

The Regional Sales Manager at Carrier Rental Systems, who oversaw the project, said: “Plant downtime due to temperature cut-outs was proving extremely costly for the client, due to the high-value nature of the products. It was essential to put a temporary cooling solution in place quickly to restore full plant operation. CRS acted swiftly to assess the requirement and meet the need.”