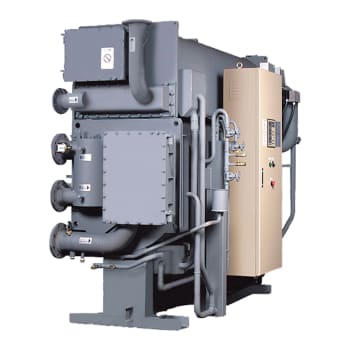

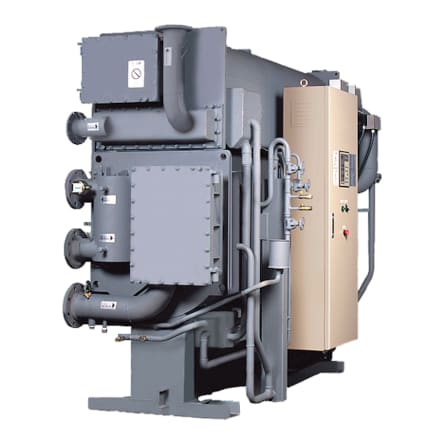

Single-effect steam-fired absorption chiller

16TJ

Nominal cooling capacity : 350-2 500 kW

For all cases where power grid is not available on site or either not extensively developed, or where thermal energy sources (water or steam) are available on site, Carrier offers a complete range of absorption chillers.

- Complete range 350 to 2 500 kW

- HFC-refrigerant free

- Steam supply pressure 50 to 100 kPa

- Designed for cooling applications where low-pressure steam is available as waste heat

- Can tie into district steam systems

- Absorption chillers allow diversification of critical cooling requirements. Critical cooling loads are met with minimal electrical power input

- Allow smaller emergency generators compared to an electrical driven chiller

- Ozone-safe and CFC-free. Cooling requirements are met without chlorine-based refrigerants

- Absorption chillers reduce the contribution to global warming and minimize the global impact by greatly reducing electricity consumption and production of greenhouse gases

- The solution inhibitor has no impact on the environment

- An absorption chiller does not utilize mechanical moving parts, and this leads to quiet, vibration-free operation

- The use of high-efficiency heat transfer surfaces has reduced the space required for installation of the absorption chiller, resulting in a smaller footprint

- Expert self-diagnosis function to monitor operating conditions, predict chiller information and maintain stable operation

- Predictive maintenance information

- Carrier control system

- Fast digital PID control stabilizes the chilled/ hot water temperature with high accuracy. It quickly responds to the load fluctuation and supplies stable chilled/hot water temperature. It is suitable for air-conditioning intelligent buildings which require sophisticated control

- Saving energy with the inverter (option). Running cost is decreased by 5% compared to non-inverter control

- High-performance purge system maintains the required operating pressure and minimizes chiller maintenance to one purge operation per season (for year-round operation)

- Hot-water valve opening control

- Expansion of safe operating zone

- Crystallization protection

- Designed for cooling applications where low-pressure steam is available as waste heat

- Can tie into district steam systems

- Absorption chillers allow diversification of critical cooling requirements. Critical cooling loads are met with minimal electrical power input

- Allow smaller emergency generators compared to an electrical driven chiller

- Ozone-safe and CFC-free. Cooling requirements are met without chlorine-based refrigerants

- Absorption chillers reduce the contribution to global warming and minimize the global impact by greatly reducing electricity consumption and production of greenhouse gases

- The solution inhibitor has no impact on the environment

- An absorption chiller does not utilize mechanical moving parts, and this leads to quiet, vibration-free operation

- The use of high-efficiency heat transfer surfaces has reduced the space required for installation of the absorption chiller, resulting in a smaller footprint

- Expert self-diagnosis function to monitor operating conditions, predict chiller information and maintain stable operation

- Predictive maintenance information

- Carrier control system

- Fast digital PID control stabilizes the chilled/ hot water temperature with high accuracy. It quickly responds to the load fluctuation and supplies stable chilled/hot water temperature. It is suitable for air-conditioning intelligent buildings which require sophisticated control

- Saving energy with the inverter (option). Running cost is decreased by 5% compared to non-inverter control

- High-performance purge system maintains the required operating pressure and minimizes chiller maintenance to one purge operation per season (for year-round operation)

- Hot-water valve opening control

- Expansion of safe operating zone

- Crystallization protection